Chemical pumps are indispensable components for numerous industries. They permit the safe and effective mixing and dispensing chemicals. They are specially designed to handle Abrasive and corrosive liquids that aren’t compatible with standard pumps. Chemical pumps are classified into positive displacement or centrifugal pumps.

Through partnering with trusted chemical pump manufacturers You can get top-quality chemicals that are in line with industry standards. These manufacturers utilize their expertise to create chemical pumps that are reliable robust, durable, efficient and cost-effective. They use advanced technology, materials, and manufacturing methods to withstand the corrosive and abrasive nature of chemicals. Working with trusted companies firms can have access to pumps that can be able to withstand extreme conditions and function optimally.

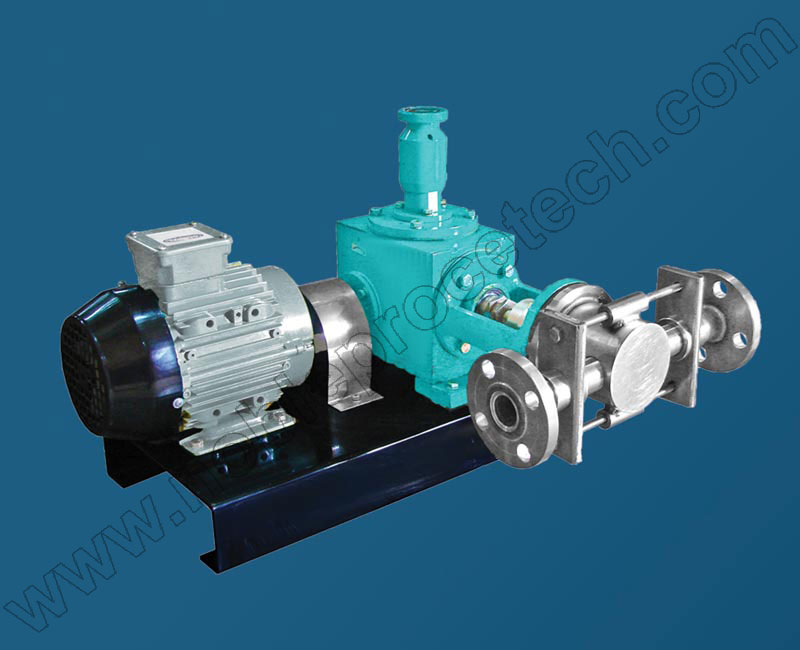

Chemical transfer pumps manufactured by manufacturers are experts in the design of pumps specifically crafted for fluid-transfer applications. They are capable of handling many different chemicals such as acetic and sulphuric acids, sodium hypochlorite and others. With the goal of maximizing chemical transfer, pump manufacturers design pumps that incorporate features such as corrosion-resistant materials seals, leak-proof seals, as well as precise flow control mechanisms. Their pumps are made to assure safe, precise and seamless chemical transfer.

Chemical pump manufacturers play a crucial role in connecting businesses with the correct pumps for their needs. They supply a variety of pumps for chemical use from reputable manufacturers. They offer extensive product catalogues as well as technical knowledge to help companies select the right pumps to meet their requirements. Chemical pump manufacturers offer various options to ensure that businesses can choose the right pump to suit their specific needs.

The importance of dependable chemical pumps goes beyond protecting fluids. These pumps are essential for maintaining the safety and integrity of an entire industrial process. An unreliable or malfunctioning pump can lead to expensive leaks, inefficient operation as well as potential risks. In industries in which chemicals are used like chemical manufacturing or petrochemical industry The consequences of a pump failure are often severe. For more information, click chemical transfer pump manufacturer

By investing in dependable chemical pumps, businesses can lessen the risks that come with handling fluids. These pumps are made to withstand the harsh nature of chemical. They are therefore able to operate reliably and consistently for a long period of time. They’re stocked with features such as robust materials, advanced sealing mechanisms, and precise flow control, each of which helps in the safety and reliability of flow of fluids.

A lot of times, chemical pumps that work include maintenance and support services. They recognize the importance of chemical pumps and provide technical support, spare part availability, and maintenance inspections. This proactive approach enables the identification and resolution of any potential problems before they get out of hand. This helps ensure continued pump reliability, and minimizes unexpected downtime.

Chemical pumps are used in a variety of industries, such as chemical manufacturing, food processing and petroleum chemicals. They are crucial for fluid transfer, mixing and dispensing in these industries. Chemical pumps are frequently used to heat high temperatures and in other applications on refineries that are not on site. They are essential to industrial processes because of their versatility and the ability to work with difficult liquids.

It is crucial to consider elements like the type of fluid that is used and the flow requirements, operating conditions and compatibility. The most reliable suppliers and manufacturers can provide advice and support in selecting the right pump for your specific needs. It is important to focus on safety as well as efficiency and reliability when choosing a pump to reduce the risk of accidents or accidents, maximize productivity, and decrease interruptions.

Chemical pumps have applications that go far beyond the refinery. They have an important role in the off-site operation. They are essential to the secure and efficient transfer of chemical in different contexts. Chemical pumps are essential for efficient refinery operations, whether they are used to move the storage of corrosive fluids or to facilitate truck loading and unloading or assist in maintenance and repair or to ensure that chemicals that are corrosive can be transported. They are crucial for any application that requires accuracy, safety and efficiency when handling corrosive and chemicals that are abrasive. With the help of reliable chemical pump suppliers and manufacturers and by investing in high-quality pumps, refineries are able to build a solid foundation for their off-site operations and ensure reliable chemical transfer.